Guide Pulleys⁚ A Comprehensive Overview

Guide pulleys are essential components in various mechanical systems, playing a critical role in guiding and redirecting cables, belts, and chains. These simple yet effective devices offer a smooth and efficient way to manage movement, contributing significantly to the performance and longevity of machinery.

Introduction

Guide pulleys, often referred to as snail pulleys, are fundamental mechanical components that serve a crucial function in directing and controlling the movement of cables, belts, and chains within various systems. These devices, typically consisting of a grooved wheel mounted on a bearing, act as essential guides, ensuring smooth and efficient operation by preventing the cable, belt, or chain from deviating from its intended path. The design of guide pulleys prioritizes minimal friction, allowing for effortless movement and preventing undue wear on the system. They are widely employed across a diverse range of industries, from simple curtain track diverters to complex hoisting systems, demonstrating their versatility and indispensable role in optimizing mechanical performance.

Types of Guide Pulleys

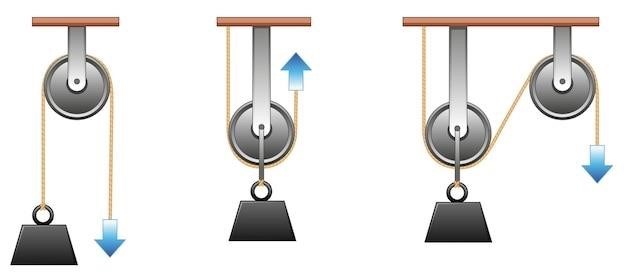

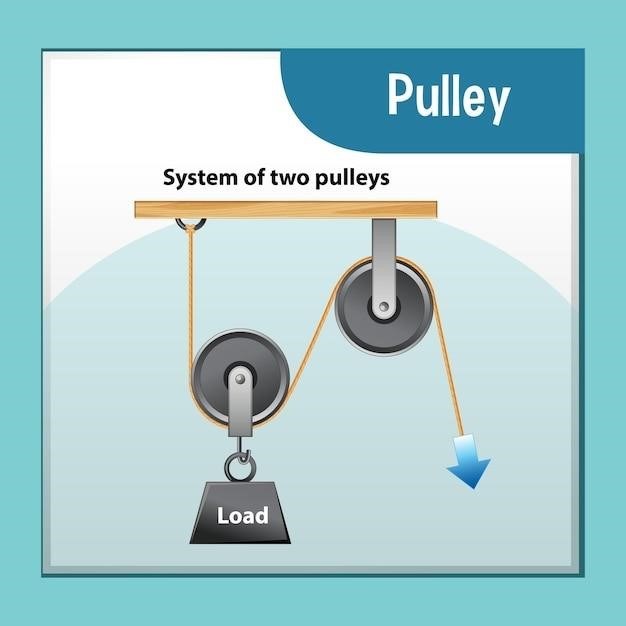

Guide pulleys come in a variety of configurations, each tailored to specific applications and demands. A common distinction is between mounted and hanging pulleys. Mounted pulleys are fixed to a structure, providing a stable anchor point for the cable or belt. Hanging pulleys, on the other hand, are suspended from a point and can be easily adjusted as needed. Another classification is based on the type of material used. Guide pulleys can be constructed from metal, plastic, or even rubber, depending on the required strength, durability, and environmental conditions. The shape and size of the pulley also play a crucial role. Grooved pulleys are designed to accommodate specific belt types, while smooth pulleys are more versatile and can handle a range of cables and chains. Furthermore, guide pulleys can be equipped with additional features, such as damping elements, which help absorb vibrations and reduce wear on the system.

Applications of Guide Pulleys

Guide pulleys find widespread use in various industries, contributing to the smooth operation of numerous mechanical systems. They are indispensable in hoisting systems, where they facilitate the vertical movement of loads. In these applications, guide pulleys ensure that the cables remain aligned and prevent them from slipping or tangling. They are commonly found in cranes, elevators, and other heavy-duty lifting equipment. Another crucial application is in cable and belt systems, where guide pulleys direct the movement of cables and belts, ensuring optimal performance and preventing premature wear; They are essential in conveyor systems, transmission systems, and other applications where precise and controlled movement is critical. Beyond these core applications, guide pulleys also find use in a variety of other scenarios, such as in window blinds, garage door systems, and even bicycles, where they contribute to smooth and efficient operation.

In Hoisting Systems

Guide pulleys play a crucial role in hoisting systems, ensuring the safe and efficient movement of heavy loads. They are essential for maintaining the alignment of lifting cables, preventing them from slipping or tangling, which could lead to accidents and damage. In cranes, for instance, guide pulleys are strategically positioned to direct the cables around the structure, ensuring smooth and controlled lifting operations. Elevators rely on guide pulleys to guide the cables that connect the car to the motor, enabling the safe and smooth vertical travel of passengers. These pulleys are typically made from durable materials, such as steel or aluminum, to withstand the heavy loads and constant stress they experience. Their robust design ensures longevity and reliability, contributing to the overall safety and efficiency of hoisting systems.

In Cable and Belt Systems

Guide pulleys are essential components in cable and belt systems, ensuring smooth and efficient operation; They play a critical role in redirecting and maintaining the alignment of cables and belts, preventing them from slipping or wearing prematurely. In conveyor systems, guide pulleys are used to direct the movement of belts carrying materials, ensuring a consistent flow. They are strategically positioned along the conveyor path, keeping the belt centered and preventing it from running off track. In cable-driven machinery, such as cable cars or ski lifts, guide pulleys are used to change the direction of cables and maintain tension, ensuring safe and reliable operation. These pulleys are often designed with specific grooves or flanges to accommodate the size and shape of the cables or belts, ensuring proper contact and reducing wear and tear. Their robust construction and precise design contribute significantly to the overall efficiency and longevity of cable and belt systems.

In Other Applications

Beyond their common use in hoisting and cable/belt systems, guide pulleys find applications in diverse industries. They are used in window blinds and shutters, where “snail pulleys” guide the movement of the blinds, enabling smooth and controlled operation. In the construction industry, guide pulleys are essential for trenchless rehabilitation techniques, where they are used to guide liners into pipes, facilitating efficient and minimally invasive repairs. They are also found in automotive applications, such as tensioning systems for V-belts, where they ensure proper belt tension and prevent premature wear. Furthermore, guide pulleys are used in recreational activities, like archery, where they are incorporated into bows to ensure smooth and efficient string release. Their adaptability and versatility make them valuable components in a wide range of applications, contributing to improved performance and reliability in various industries.

Advantages of Guide Pulleys

Guide pulleys offer a number of advantages that make them indispensable in a variety of applications. Their primary benefit is their ability to efficiently redirect and guide cables, belts, and chains, minimizing friction and wear. This smooth movement ensures optimal performance and longevity of the system. Guide pulleys also contribute to increased safety by preventing cables from tangling or becoming entangled, which can be crucial in heavy-duty machinery. They also provide a reliable and predictable force transfer, ensuring consistent operation and reducing the risk of malfunctions. Furthermore, guide pulleys are relatively inexpensive to manufacture and maintain, making them a cost-effective solution for a variety of applications. Their compact size and lightweight design make them easy to install and integrate into existing systems, further enhancing their practicality and appeal. In summary, guide pulleys offer a combination of efficiency, safety, reliability, and affordability, making them an essential component in a wide range of mechanical systems.

Selection and Installation of Guide Pulleys

Selecting the right guide pulley involves considering factors like the type of cable or belt, load capacity, operating environment, and desired speed. For instance, a guide pulley for a hoisting system in a mine might require a robust construction with high load capacity, while a guide pulley for a curtain track might prioritize smooth operation and minimal noise. Once the appropriate guide pulley is chosen, proper installation is crucial for optimal performance and safety. This typically involves securely mounting the pulley to a stable surface using appropriate fasteners. It’s essential to ensure the pulley is properly aligned with the cable or belt path, minimizing friction and wear. Additionally, regular inspection and maintenance are vital to prevent premature wear and ensure the longevity of the guide pulley. This might involve checking for signs of damage, lubrication, and adjusting the tension of the cable or belt. By meticulously selecting and installing the guide pulley, you can ensure it effectively performs its role and contributes to the overall efficiency and longevity of the system.

Guide pulleys are fundamental components in various mechanical systems, playing a crucial role in enhancing efficiency, reducing wear, and ensuring smooth operation. From hoisting systems in mines to simple curtain tracks, guide pulleys offer a reliable and efficient way to manage movement. Their versatility and adaptability make them essential for a wide range of applications. When selecting and installing guide pulleys, careful consideration of factors like load capacity, operating environment, and alignment is crucial for optimal performance and longevity. Regular inspection and maintenance are also essential to prevent premature wear and ensure the continued effectiveness of these vital components. In conclusion, guide pulleys are an essential element in numerous mechanical systems, contributing significantly to their overall efficiency, safety, and longevity. Their simple yet crucial role underscores their importance in the world of engineering and mechanics.